Tape thread sealing tape PTFE GRP DVGW

- Model

- TF12-10/0.6

Item specifics

- Company Logo

- Foreverseal

- Busniess type

- PTFE TAPE Manufacturer

- Brand

- OEM/ODM

- Specification

- 12mmx0.1mmx10m

- Density

- 0.60g/cm3--1.80g/cm3

- Color

- White

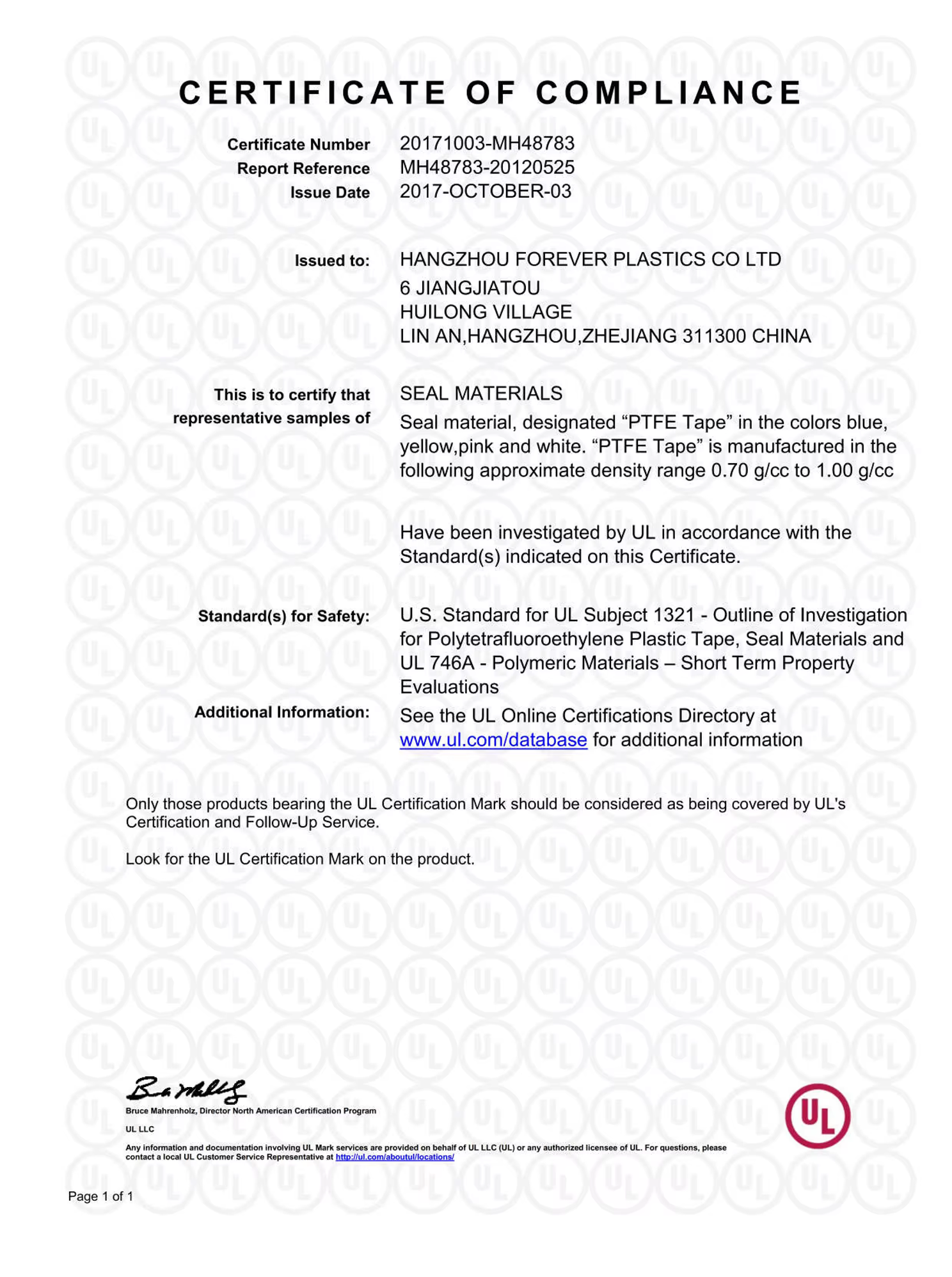

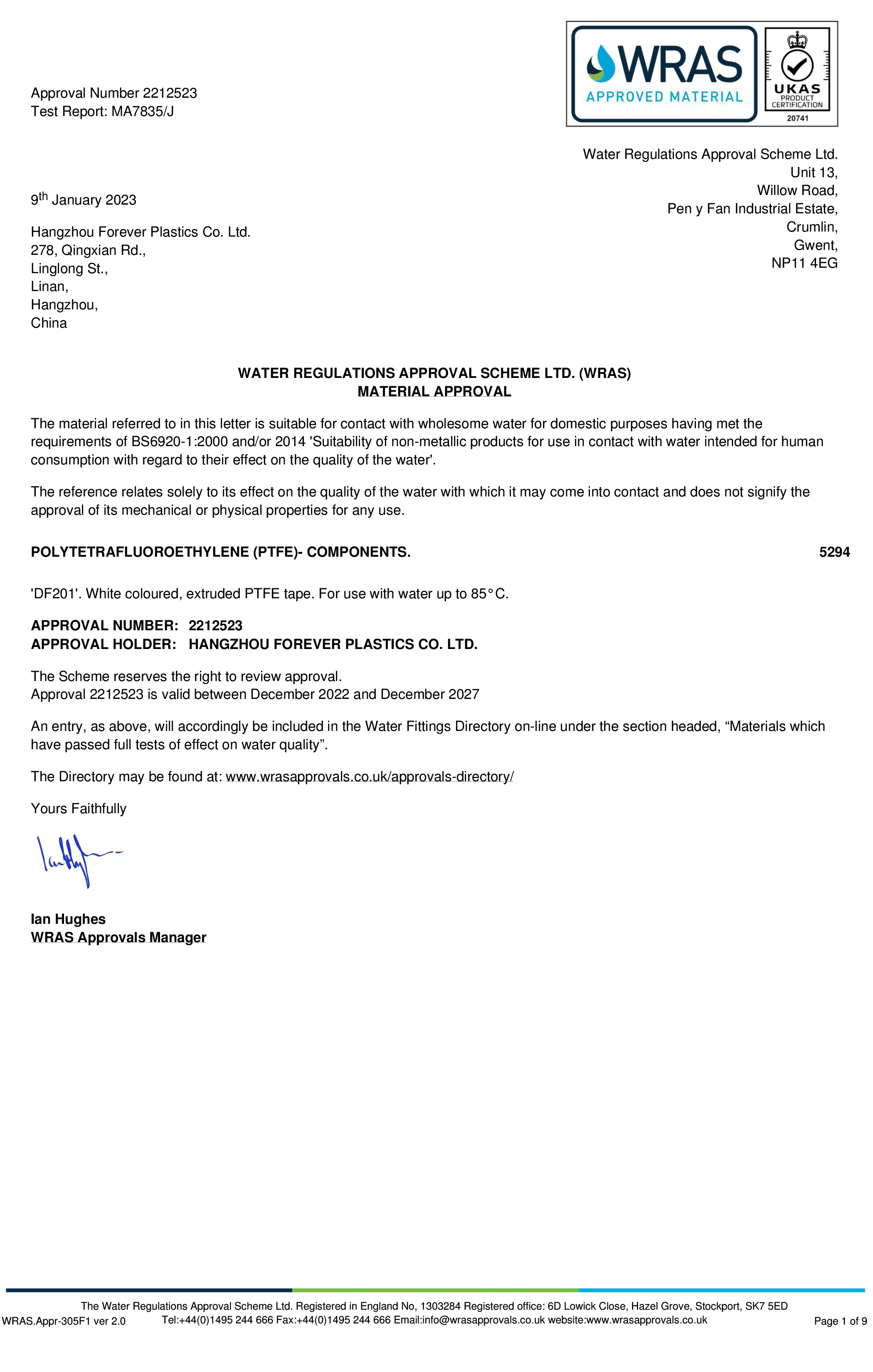

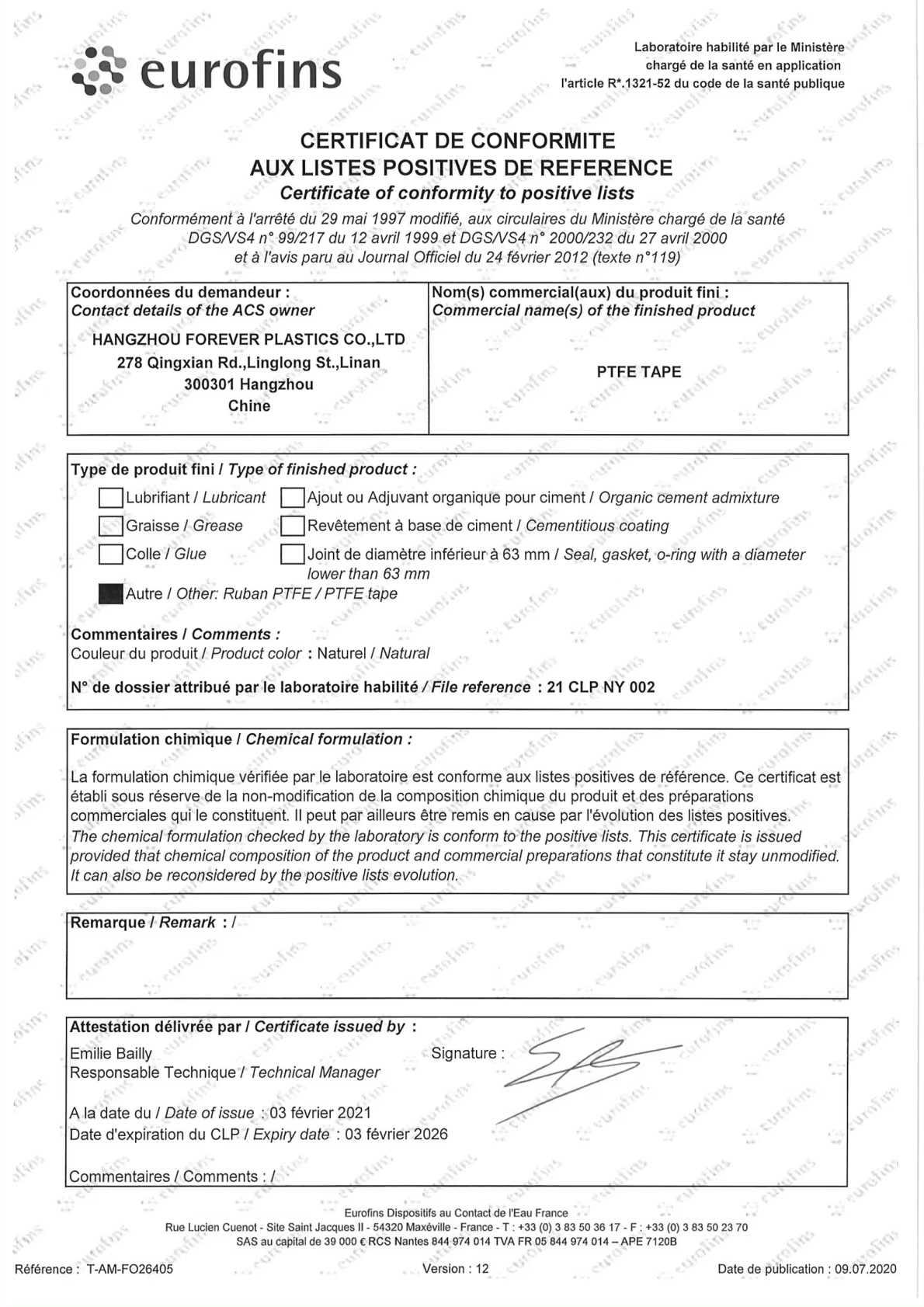

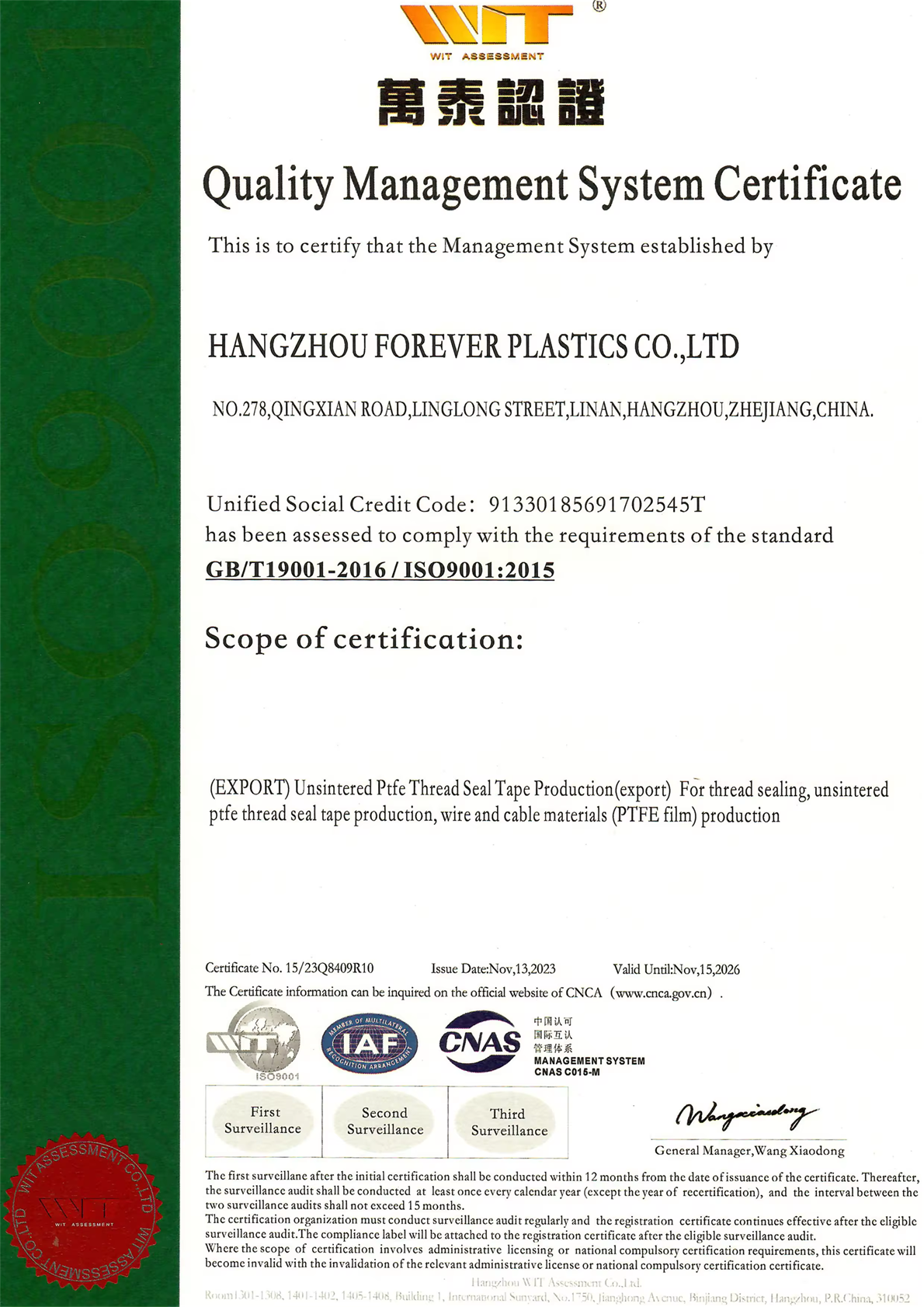

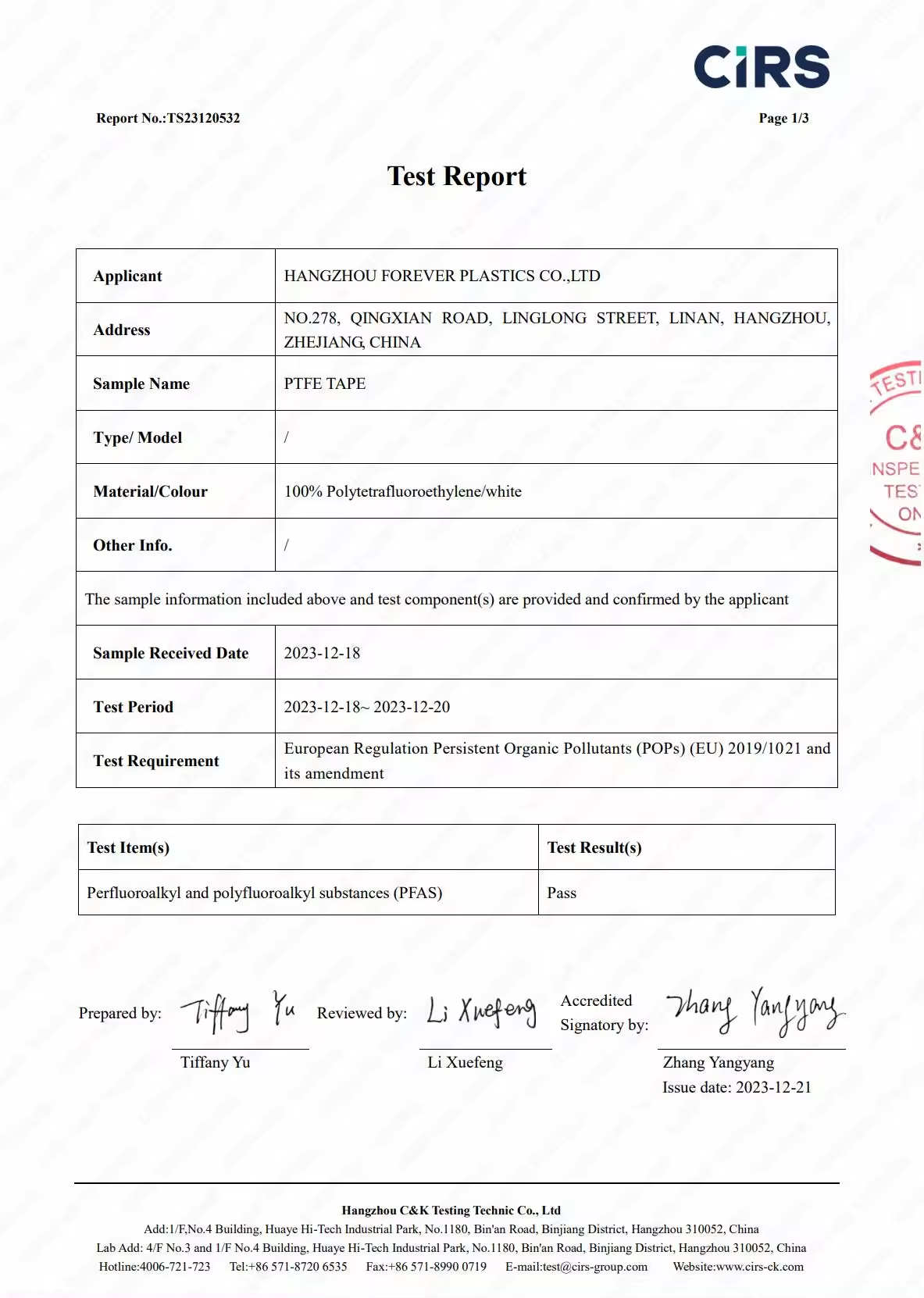

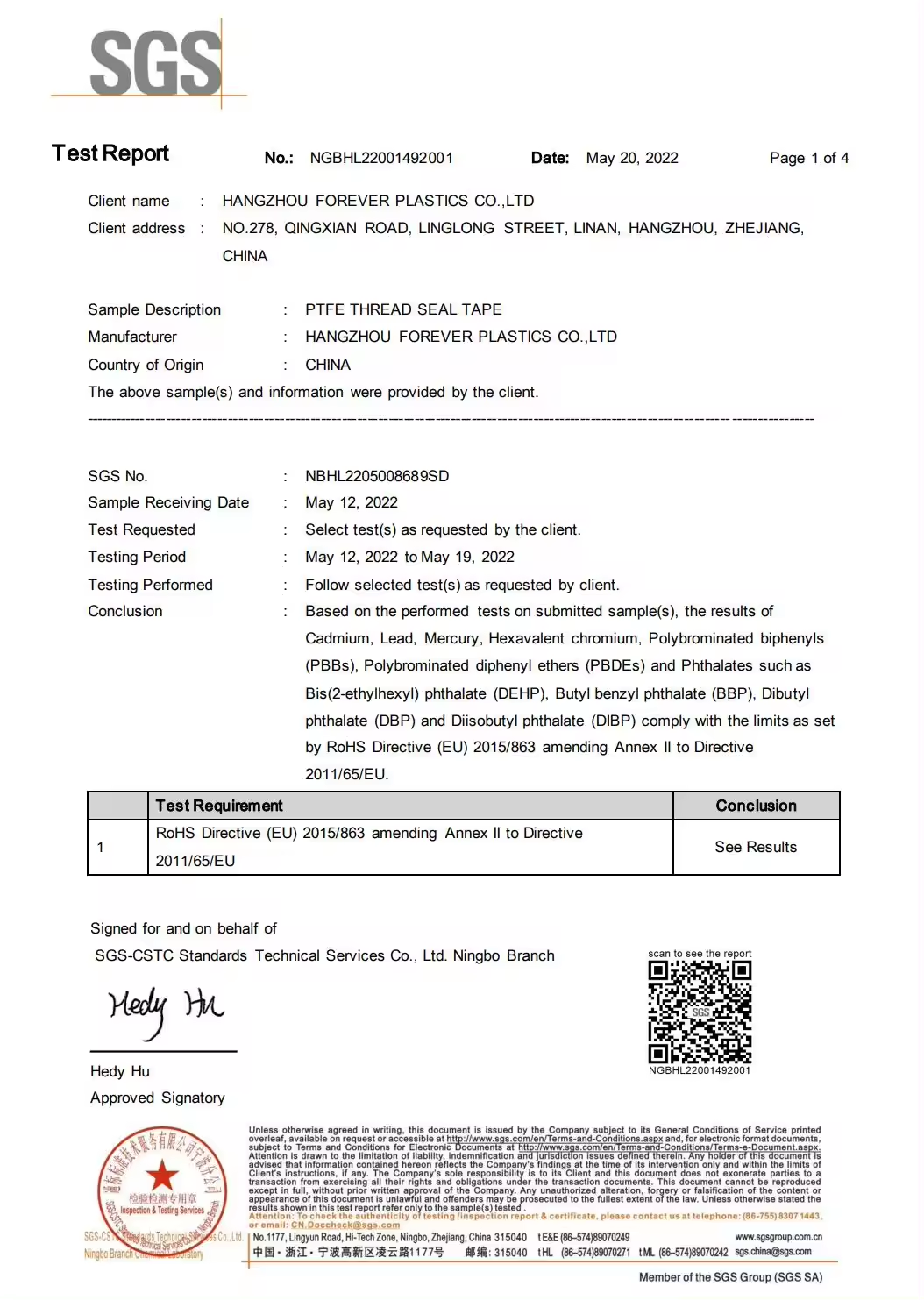

- Certificate

- DVGW,ISO9001,CE,UL,RoHS,WRAS,ACS

- Composition

- Min. 99% virgin PTFE, Max. 1% pigment

- Temperature Range

- -450F(-268C) to +500F ( 260C)

- Tensile Strength

- 15N/mm2

- Elongation

- Min 50%

- Pressure Resistance

- up to 10,000PSI

- Chemical Resistance

- PH:0-14

Review

Description

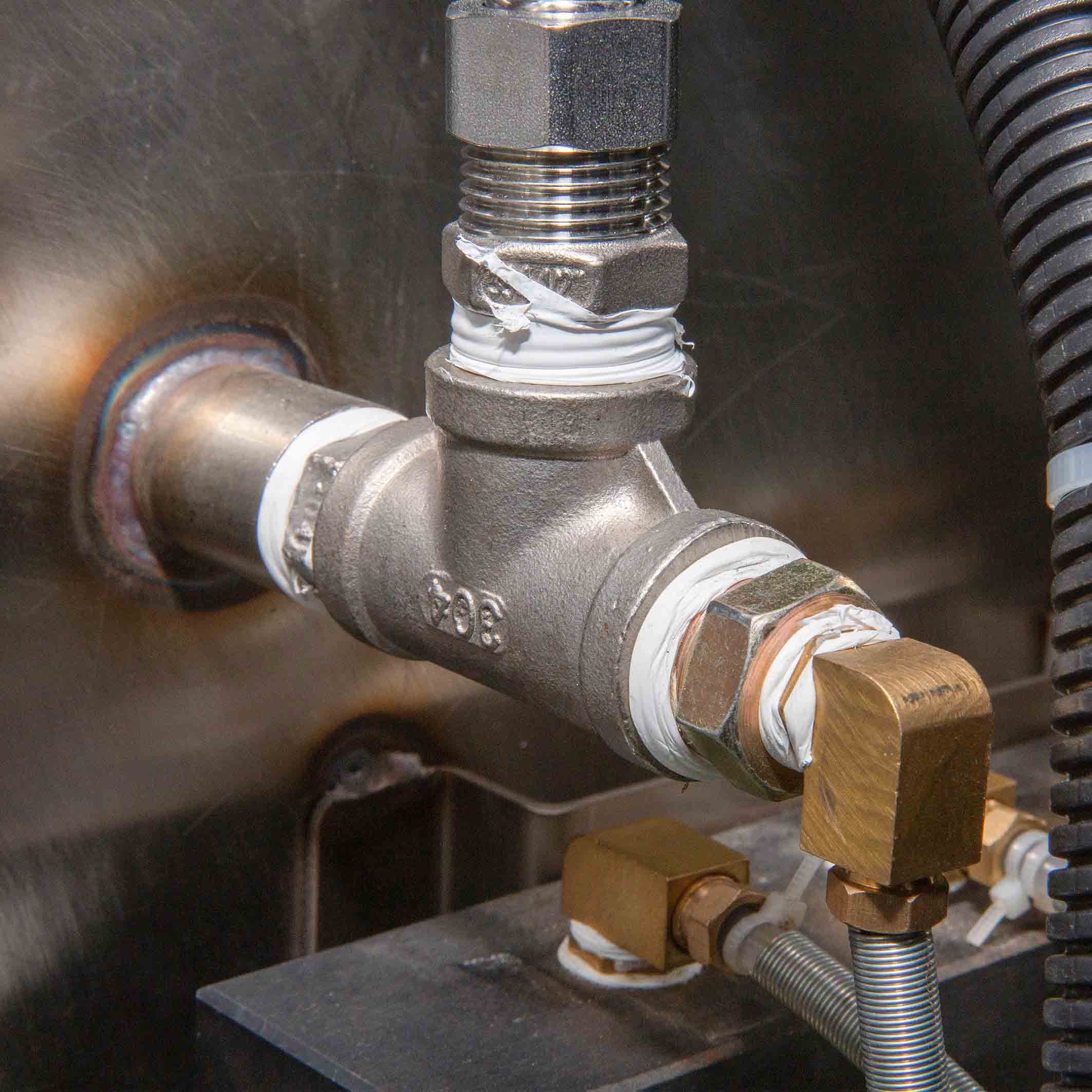

High density PTFE TAPE for gas pipe are used for high pressure systems,for critic and special purpose. According to MIL-T27730A, UL.

High density PTFE TAPE is thicker and heavier tape. it's easy to apply and creates a more effective seal with less tape,and no need for pipe dope. It's used on all threads made by galvanized steel,iron,brass copper,aluminum,stainless steel,polyethylene,polypropylene,pvc,cpvc,abs,fiberglass and more.

Thickness | 0.1mm | ||

Width | 12mm(1/2") | ||

Density | 0.6g/cm3 - 1.80g/cm3 | ||

Composition | 100% virgin PTFE | ||

Pressure Rating | up to 3,000PSI | ||

Temp.Range | 400F to +500F (-240C to 260C) | ||

Tensile Strength | 8 N/mm2 | ||

Elongation | Min 25% | ||

Storage | Unlimited shelf life(less than 70F )/50% relative humidity out of direct sunlight | ||

Flammability | Non-flammable | ||

--China's two largest suppliers

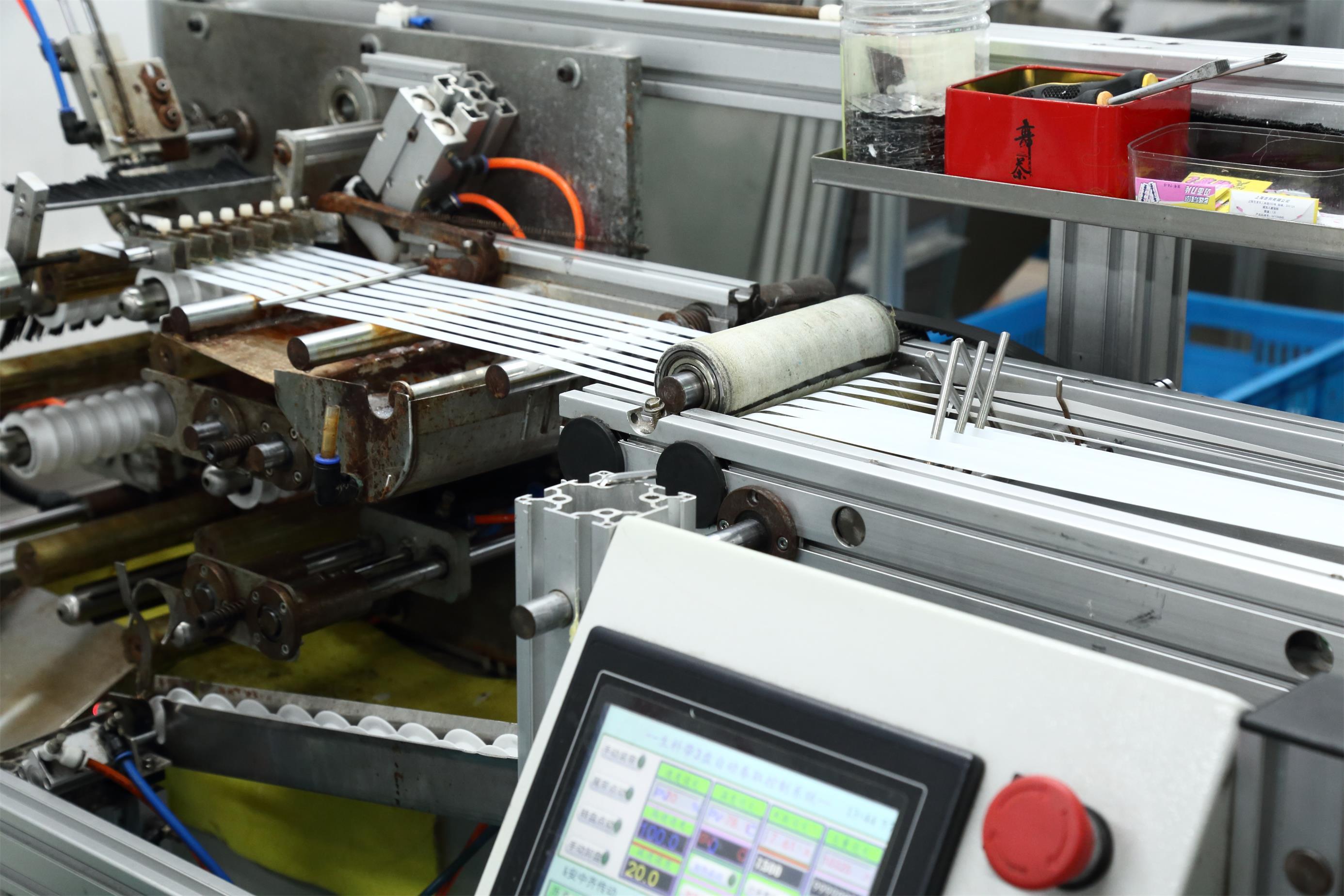

AUTO INJECTION MACHINES

At end of 2019, we have invested 3 million RMB to 9 auto Injection molding machines, it's saved 50% labor cost and improved the spool/cover quality. It's worthy as we are always focus to the quality

Since 2012, with significant investment in both Research&Development for all production line, we have already introduced automatic machines to improve the work efficiency and product quality.

From mixing, calendering, stretching, slitting, rewinding and packing, our well-equipped facilities and professional quality control through all stages of production enable us to guarantee total customers’ satisfaction.